A LANDMARK PROJECT: TOTAL WRECKING & ENVIRONMENTAL’S DEMOLITION OF MCKEE RUN GENERATING STATION

Some demolition services are just another day at the office. Others? They embody everything we love about the work we do.

The McKee Run Generating Station in Dover, Delaware was one of those projects — big, complex, and packed with challenges. Built in 1961, this power plant had been literally keeping the lights on for decades, but by 2021, it was officially out of juice. The city needed it gone.

Safely. Efficiently. With as little impact on the surrounding community as possible. That’s where Total Wrecking & Environmental stepped in.

From the moment we won the bid, we knew this was going to be the kind of job we talked (and hopefully bragged) about for years to come. The site was right next to a residential neighborhood, meaning there was zero room for error. We had to be surgical — no dust storms, no noise complaints, and absolutely no cutting corners. And last but certainly not least, we had to make sure as much of the material as possible was recycled, all while staying on budget and finishing ahead of schedule.

Fast forward nine months later — yes, ahead of schedule — and McKee Run was nothing but a clean, graded lot. 95% of materials were recycled, not a single resident complaint was filed, and we racked up 36,000+ safe work hours with zero incidents. Not bad for a day’s work… or, you know, almost a year’s work.

So how did we pull it off? Let’s take a look.

BEFORE THE DEMOLITION: THE LEGACY OF MCKEE RUN

Built in 1961, this plant was a workhorse. It started with two Westinghouse 16.5 MW units running on coal, then shifted to fuel oil and natural gas in the 1970s. By 2008, it was burning No. 2 fuel oil and gas, trying to keep up with changing regulations. But no matter how many upgrades it went through, one thing became increasingly clear to Dover city officials — its days were numbered.

By 2017, two of its three units had been retired, and by June 2021, the entire plant had officially powered down for good. Why? The same reason so many older power plants are disappearing — tighter environmental regulations, aging infrastructure, and the push for cleaner, more efficient energy. It was time for Dover to move on.

WHY CALL IN TOTAL WRECKING?

When the City of Dover decided McKee Run had to go, they didn’t just pick a demolition company out of a hat. This was a high-profile, high-risk job, and they needed the right team for it. So, they put the project out for competitive bidding, a process that included bid submissions, contractor shortlisting, public city council meetings, and multiple rounds of interviews.

Total Wrecking & Environmental won the contract not just because we know how to take down power plants (though we have a very long and proven track record doing just that), but because we understand the bigger picture.

• Safety-first approach?

• Sustainability-driven methodology?

• Community-focused execution? 100%.

Dover’s biggest concern was making sure residents weren’t impacted by noise, dust, or disruptions, and like every jobsite we’ve worked on, we were all-in on making that happen.

THE GAME PLAN

The city expected the project to take 10-14 months, a very fair estimate given the scale of work ahead. But we had other plans. Our goal? Get it done faster, safer, and cleaner than expected.

Spoiler alert: we finished the project top to tail in just 9 months.

With a 46-person crew split between demolition and asbestos abatement, we mapped out a step-by-step strategy to take McKee Run apart methodically, a detailed plan that preserved valuable materials, minimized disruptions, and ensured every safety measure was locked in place.

Up next? The real work begins. Let’s break down how we tackled the demolition, piece by piece.

THE DEMOLITION PROCESS: STEP BY STEP

Taking down a power plant isn’t like knocking over an old building. You can’t just bring in an excavator, swing a wrecking ball, and call it a day. There’s hazardous material to remove, valuable equipment to salvage, and a whole lot of planning to make sure the process is safe, controlled, and efficient.

Here’s how we dismantled McKee Run Generating Station, one step at a time.

Phase 1: Prepping the Site

Before the first piece of steel came down, we had one job: make the site safe and secure. That meant:

• Disconnecting all remaining utilities

• Setting up dust control measures to keep the neighborhood happy

• Coordinating with city officials to ensure permitting and compliance

Once the groundwork was laid, it was time to start clearing out the hazardous stuff.

Phase 2: Handling Hazardous Materials

Like any older power plant, McKee Run had its fair share of hazardous materials, from asbestos in the building materials to universal waste, oil, and electronic components that needed careful removal.

This part of the job fell to our 23-person abatement crew, who worked in tandem with the demolition team to safely extract and dispose of everything properly.

Key steps included:

• Asbestos Abatement – Systematic removal of all asbestos-laced materials before demolition could begin.

• Hazardous Waste Extraction – Removing universal waste, transformer oils, mercury switches, and old wiring that couldn’t go straight to scrap.

• Salvaging Valuable Materials – Copper wiring and massive turbine shafts were carefully cut and rigged for removal in order to be safely repurposed.

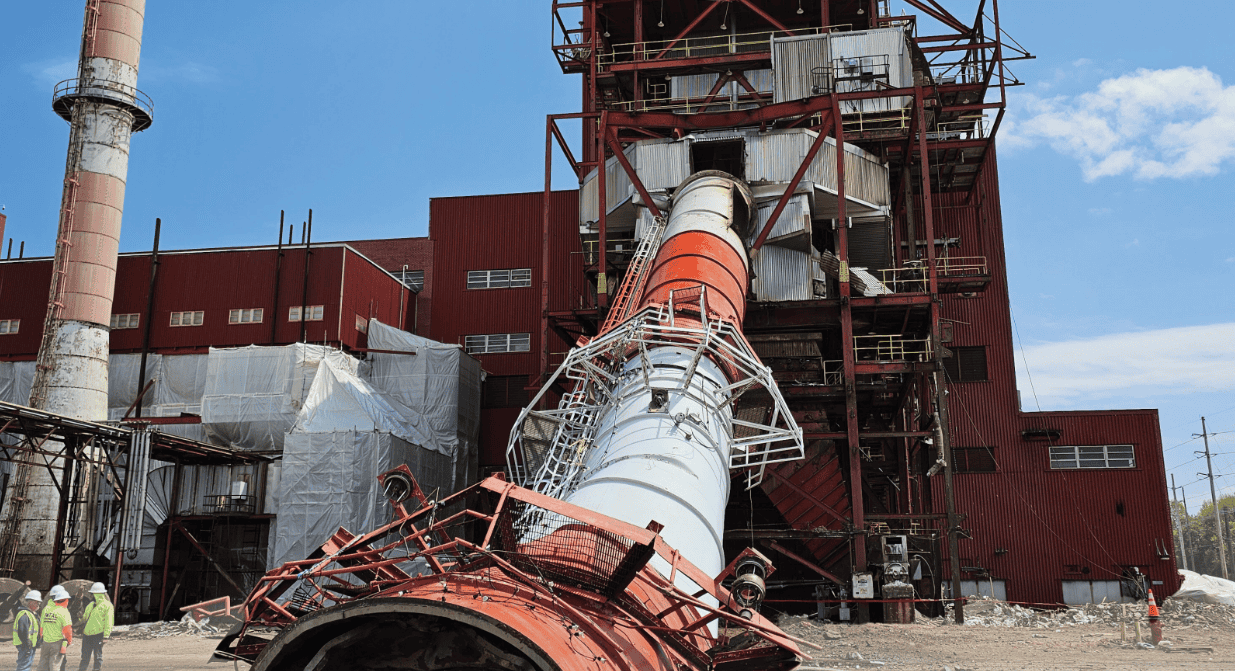

Phase 3: Mechanical & Structural Demolition

With the site prepped and hazardous materials removed, we could move on to the really fun part — bringing down the structures.

Our biggest demolition areas included:

Cooling Towers

• These massive structures (155’ x 53’ and 180’ x 54’) had to be taken down piece by piece.

• They were constructed with a mix of pressure-treated wood, fiberglass, and plastic trays, making demolition tricky.

Turbine & Boiler Removal:

• Using 6-foot torches, our team carefully cut through turbine shells to extract the heavy-duty shafts.

• Every cut was surgical and tightly controlled, ensuring no unexpected collapses.

Powerhouse Demolition:

• This was the heart of the plant, containing boilers, turbines, generators, transformers, and massive steel structures.

• Our high-reach excavators (110 feet tall!) were key in methodically bringing down each section.

Equipment that made it happen:

• 100,000-pound excavators with shears, grapples, and hydraulic hammers

• 110-ft high-reach excavator for precision work

• 6-ft torches for controlled dismantling

• 950 front loader & 10,000-lb telehandler for material handling

Phase 4: Water Line Grouting & Site Restoration

Even after the major structures were down, we still had some housekeeping to do around the jobsite, including:

• Water Line Grouting – Abandoned underground water lines needed to be sealed and flow-filled to prevent future ground shifts.

• Final Grading & Leveling – The site was backfilled, graded, and leveled to create a clean slate for future redevelopment.

THE RESULTS: A PROJECT COMPLETED WITH EXCELLENCE

When you take down a massive industrial facility like McKee Run, it’s about doing it right. Safety, efficiency, sustainability, and community impact all play a role in measuring success.

Finishing Ahead of Schedule

The City of Dover estimated this project would take 10 to 14 months, which is a totally reasonable timeline considering the complexity of power plant demolition.

But Total Wrecking doesn’t aspire to do “totally reasonable” work.

Instead of 10-14 months, we wrapped it up in just 9. That’s months ahead of schedule, without cutting a single corner and to a level of quality you simply can’t find with another industrial or commercial demolition contractor.

How did we do it? Meticulous planning, expert crews, and a dedication to everyone working in lockstep every step of the way.

36,000+ Safe Work Hours

Demolition is extremely dangerous work, and safety at Total Wrecking is non-negotiable. One wrong move in a job like this could mean serious injuries, or worse.

That’s why every single one of our extensively trained 46 crew members followed strict safety protocols from day one, which resulted in:

• Zero safety incidents

• 36,000+ incident-free work hours

• No injuries, no delays, no mishaps

We don’t mean to pat ourselves on the back, but where we come from, stats like that aren’t just good — they are unequivocally the gold standard in this industry.

95% of Materials Recycled

A demolition site is a gold mine of recyclable materials, especially if you know what you’re doing. And we do.

Rather than sending everything to a landfill, we made sure to salvage and repurpose as much as possible:

• Turbine shafts – Carefully cut and removed for resale

• Copper wiring – Extracted and recycled

• Steel & scrap metal – Processed for reuse

• Other recoverable materials – Diverted from waste streams

The only materials that couldn’t be reused were the cooling towers. Everything else was safely reclaimed, recycled, or repurposed.

Zero Resident Complaints

One of the biggest concerns with a project like this is not disrupting the surrounding community.

McKee Run sat right next to a residential community, which meant we had to be surgical in our execution. Noise, dust, and traffic disruptions could have easily led to frustrated residents and city officials.

But thanks to our careful demolition strategy, dust control measures, and community engagement efforts, the project resulted in:

• Zero noise complaints

• Zero dust complaints

• Zero concerns from residents

In fact, the City of Dover’s Electric Director, Paul Waddell, praised our team in a glowing letter of recommendation, praising how our team showed up to a community meeting before the project even started to answer questions and address concerns, kept communication open and transparent throughout the entire demolition, and took extra steps to minimize impact on the surrounding area.

And it paid off! The entire project was completed without a single complaint.

A BENCHMARK FOR INDUSTRIAL DEMOLITION

For Total Wrecking & Environmental, and we hope for the entire industry at large, the McKee Run project was a case study in how to do things the right way.

Total Wrecking didn’t just meet expectations, we blew right past them. And we’re proud of that. We finished ahead of schedule, kept every single crew member safe, recycled nearly everyone on-site, and left the community happier than we found.

With McKee Run now just a memory, Dover has a clean site ready for future redevelopment, and we have yet another major success story under our belt.

Now, we’re looking forward, more prepared than ever for the next big challenge.