INTRODUCTION

Demolishing a paper or pulp mill is no ordinary project. These large industrial facilities bring the same complexity seen in many commercial and industrial demolition jobs — hazardous materials, intricate machinery, and strict environmental rules.

But these projects are more than tearing down structures. They represent opportunities to apply specialized expertise, technological innovation, and advanced safety and sustainability practices.

UNDERSTANDING PAPER & PULP MILL DEMOLITION

Paper and pulp mills are complex, housing:

-

Heavy machinery

-

Interconnected infrastructure

-

Potentially hazardous materials

Before work begins, Total Wrecking performs comprehensive assessments. These evaluate structural integrity, environmental risks, and the presence of contaminants like asbestos and chemicals. Thorough evaluations ensure safety, efficiency, and regulatory compliance at every level.

UNIQUE CHALLENGES IN DEMOLISHING PAPER & PULP MILLS

Several factors set these demolitions apart:

-

Hazardous Materials: Asbestos, lead, and chemical residues spread across large facilities require specialized abatement.

-

Heavy Machinery: Equipment such as presses, digesters, boilers, and kilns must be dismantled carefully for reuse or safe disposal.

-

Structural Complexity: Interconnected buildings and load-bearing frameworks demand phased, strategic demolition.

-

Environmental & Safety Risks: Dust, debris, and chemical residues create hazards for workers and surrounding communities.

ENVIRONMENTAL CONSIDERATIONS & MITIGATION STRATEGIES

Total Wrecking adopts a proactive approach to limit environmental impact:

-

Pre-Demolition Assessments: Hazardous materials are identified early, with mitigation plans developed before work begins.

-

Hazardous Material Abatement: Certified teams remove asbestos and toxic chemicals safely, with strict containment practices.

-

Dust & Air Control: Water suppression, dust agents, and real-time monitoring protect workers and nearby communities.

-

Waste Management & Recycling: Steel, concrete, and wood are separated for reuse, while hazardous materials are isolated for safe disposal.

-

Water & Soil Protection: Barriers and drainage systems prevent contaminated runoff from spreading

PROJECT MANAGEMENT: A TAILORED APPROACH TO COMPLEXITY

Managing a paper mill demolition requires careful planning and coordination. Total Wrecking focuses on:

-

Detailed Pre-Planning: Risk assessments and contingency plans for hazards like chemical spills or structural failure.

-

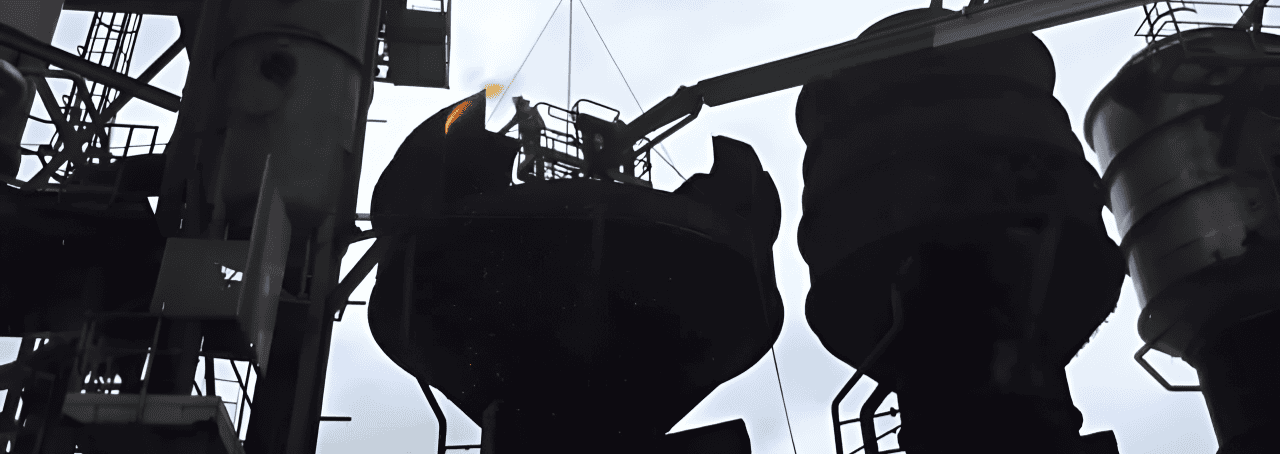

Specialized Equipment Coordination: Cranes, attachments, and remote-controlled excavators used for safe, precise dismantling.

-

Phased Demolition: Breaking projects into manageable stages minimizes risk and adapts to unexpected challenges.

-

Stakeholder Communication: Transparent updates keep clients, consultants, and subcontractors aligned throughout the process.

SAFETY PROTOCOLS: PROTECTING PEOPLE & THE ENVIRONMENT

Safety is a top priority. Key protocols include:

-

Hazardous Material Handling: Strict PPE and guidelines for asbestos and chemicals.

-

Controlled Equipment Removal: Certified riggers and specialty lifting equipment prevent accidents.

-

Structural Sequencing: Controlled demolition prevents sudden collapses.

-

Confined Space Work: Continuous atmospheric monitoring for tanks and pipes.

-

Emergency Preparedness: Real-time audits, on-site safety coordinators, and robust response plans.

CASE STUDY: THE HODGE, LA PAPER MILL PROJECT

The WestRock Old Bag Mill demolition highlights Total Wrecking’s capabilities:

-

Timber Salvage: Historic beams and columns were carefully dismantled for reuse.

-

Asbestos Management: Non-friable asbestos roofing was removed under strict protocols.

-

Logistical Constraints: Planning allowed demolition to proceed despite limited access and active nearby operations.

-

Outcome: The project finished on time and within budget, with lessons learned improving future salvage, logistics, and safety strategies.

TECHNOLOGICAL INNOVATIONS & COST MANAGEMENT

Technology plays a key role in efficiency and safety:

-

Drones: Used for surveys, hazard identification, and real-time progress tracking.

-

Remote-Controlled Equipment: Reduces human exposure in hazardous areas while improving precision.

-

Project Management Software: Digital platforms streamline scheduling, audits, and cost tracking.

LOOKING TO THE FUTURE: SUSTAINABILITY & THE CIRCULAR ECONOMY

Total Wrecking is committed to sustainable practices, including:

-

Maximizing Recovery: Recycling steel, wood, and other valuable materials.

-

Reducing Environmental Impact: Meeting or exceeding stringent standards for demolition waste.

-

Adapting to Regulations: Staying ahead of evolving federal, state, and local compliance requirements.

CLIENT COLLABORATION & CONCLUDING THOUGHTS

From planning through cleanup, Total Wrecking’s approach is defined by collaboration, transparency, and performance. Clients benefit from strategies tailored to their facilities, supported by a proven record of safe, efficient, and sustainable demolitions.

Paper and pulp mill demolitions are some of the industry’s most complex projects. By combining planning, technology, safety, and sustainability, Total Wrecking continues to set new standards for demolition excellence.