KEY TAKEAWAYS

- Urban demolition requires precision, planning, and strict environmental control.

- Total Wrecking specializes in selective demolition for tight, high-traffic environments.

- Projects are completed discreetly and safely, with minimal disruption to surrounding operations.

- The DEQ case study highlights Total Wrecking’s ability to work in sensitive, regulated sites.

- Every job is engineered for safety, compliance, and community continuity.

- Total Wrecking delivers clean, controlled results that prepare sites for what comes next.

INTRODUCTION

Demolition in urban environments isn’t just a matter of tearing down, it’s a matter of control. Every move affects something: the surrounding structures, utilities, air quality, and even the daily rhythm of the community nearby. At Total Wrecking & Environmental, that complexity is the job.

Whether dismantling part of an active campus facility or clearing space within a tight downtown footprint, the team approaches each project like a surgical operation, balancing engineering expertise, environmental responsibility, and operational discretion to complete work safely and without disruption.

A NEW ERA OF URBAN DEMOLITION

As cities grow and evolve, demolition projects are moving into more complex and densely developed spaces. College campuses, government facilities, and downtown business districts all present unique challenges, limited space, tight schedules, and strict safety and environmental requirements.

When hospitals, jails, and even aging shopping centers are also reaching the end of their useful lives, there is a demand for highly specialized demolition expertise.

In regions, where redevelopment is surging, these projects require a demolition partner that can perform with precision and minimal community impact.

That’s where Total Wrecking excels. With decades of experience managing high-profile, urban demolition projects, the company approaches every job with the same core priorities: safety, professionalism, and minimal disruption.

PRECISION WORK IN TIGHT, SENSITIVE ENVIRONMENTS

In an urban environment, every move counts. Surrounding structures, traffic patterns, and active utilities demand controlled and ultra selective methods, not brute force.

Total Wrecking’s selective demolition services are designed for exactly these conditions. The team uses engineered sequencing, advanced machinery, and strict environmental controls to isolate and remove specific structural components without affecting adjacent areas.

From noise mitigation and dust suppression to traffic coordination and debris management, every step is planned to ensure the community continues operating normally while the work gets done safely behind the scenes.

In older downtown areas or near critical facilities, vibration monitoring protects dated underground tunnels, utilities, and piping systems. Dust and water screens prevent airborne debris from leaving the project footprint, and wind screens or HVAC protection are installed where necessary to safeguard surrounding structures. Every plan also accounts for buried infrastructure like fiber optics and sewage raceways, unseen elements that require careful attention to prevent disruption.

PROFESSIONALISM AND DISCRETION IN ACTION: THE DEQ CASE STUDY

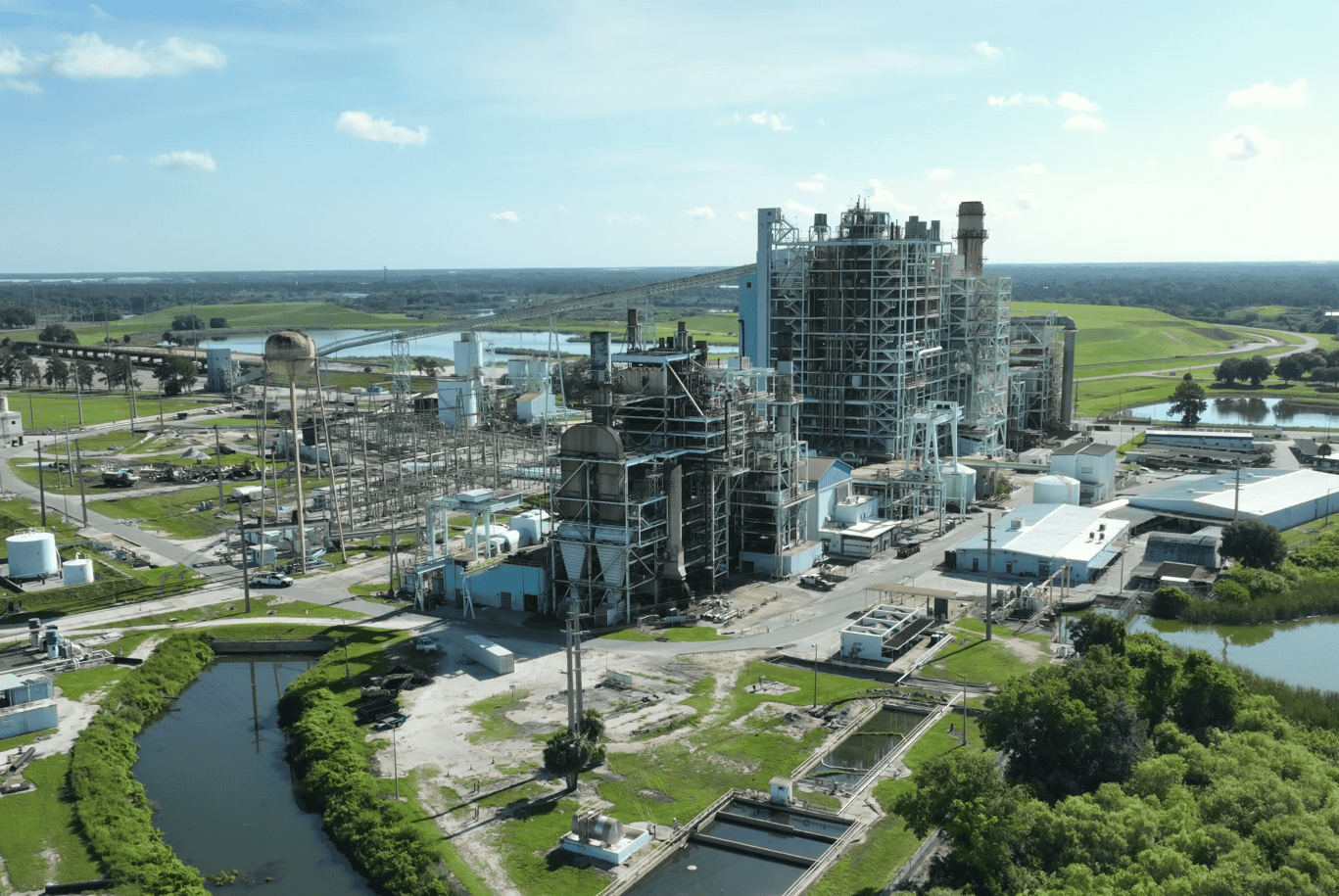

One of Total Wrecking’s recent projects with a Department of Environmental Quality (DEQ) facility showcased the company’s ability to work discreetly in an active and regulated setting.

The job required maintaining strict environmental standards while performing selective demolition inside an occupied site, a scenario where precision and professionalism were critical.

When the Oklahoma Department of Environmental Quality (DEQ) needed its seven-story parking structure demolished in downtown Oklahoma City, Total Wrecking & Environmental delivered precision in one of the most sensitive environments imaginable… right beside DEQ’s active headquarters and across from the National Memorial & Museum.

Working under Lingo Construction, the team stabilized the compromised structure with emergency bracing and protection systems before dismantling it using Brokk robotic demolition units and a Komatsu 490 UHD high-reach excavator.

Every move was engineered to limit vibration, noise, and disruption to ongoing DEQ operations.

With real-time cameras, drones, and TWE’s proprietary tracking app, progress and safety were continuously monitored, while Dust Boss suppression and adaptive recycling kept the site clean and compliant.

Despite citywide events, tight access, and severe weather, the team finished on time, on budget, and without a single safety incident, recycling over 7,000 tons of material with a 99.997% recovery rate.

As Lingo Construction’s Project Manager noted, Total Wrecking “rapidly adjusted means and methods” to overcome every obstacle, proving once again that expertise and professionalism define how complex urban demolitions get done.

Projects like these also highlight Total Wrecking’s commitment to open communication and community respect, keeping stakeholders informed and minimizing disruption to the people and properties nearby.

EXPERT EXECUTION FOR COMPLEX URBAN PROJECTS

Every urban demolition comes with unique constraints, tight access, active utilities, and strict environmental standards. Total Wrecking’s success lies in its ability to plan and execute within those limits.

Using 3D modeling, engineered sequencing, and digital project tracking, the team maps every move before a single wall comes down.

For high-risk or limited-access sites, Brokk robotic demolition units are deployed for pinpoint removal without vibration or collateral damage. High-reach excavators with custom attachments handle taller structures, while precision shears and hydraulic grapples control material separation on the ground.

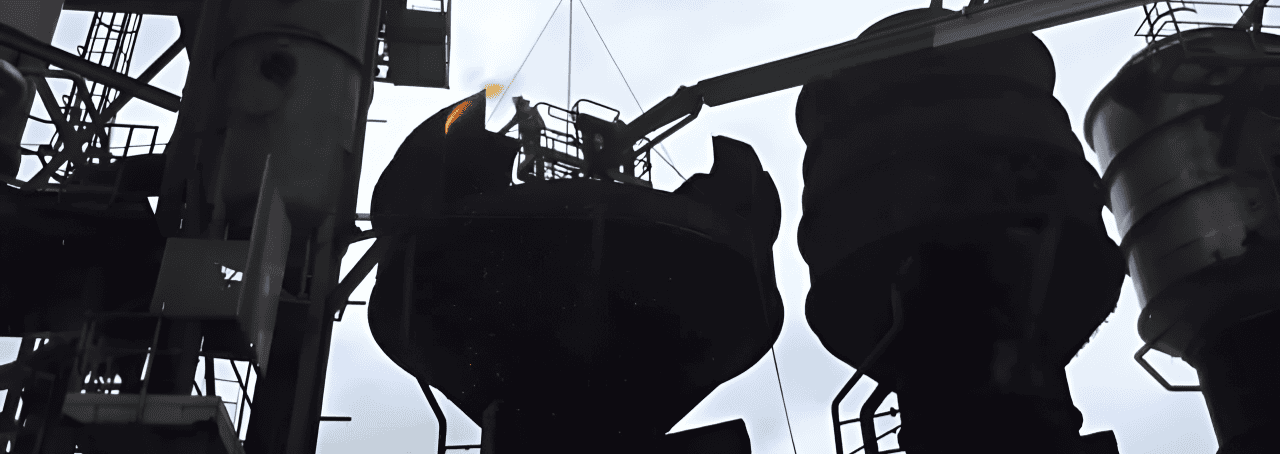

For larger or high-rise structures, Total Wrecking also utilizes a proprietary crane-suspended demolition device, designed and engineered in-house for controlled felling within confined urban or campus settings. This proprietary innovation provides greater control than conventional wrecking methods and reinforces the team’s reputation for technical excellence.

Every phase is coordinated through live site data, ensuring efficiency, safety, and minimal disruption to nearby operations.

TRANSFORMING SPACES, RESPECTING SURROUNDINGS

Total Wrecking’s selective demolition approach prioritizes sustainability and continuity as much as structural precision. Dust Boss suppression systems maintain air quality, while adaptive debris handling and recycling protocols routinely achieve industry-leading recovery rates above 99%.

The team’s focus isn’t just on removing what’s there, it’s on protecting what surrounds it. Whether separating mechanical systems inside an active lab or dismantling a façade inches from pedestrian zones, Total Wrecking ensures work happens quietly, cleanly, and responsibly, setting the stage for safe redevelopment and long-term community improvement.

That commitment starts long before demolition begins. Early conversations with local residents, businesses, and public agencies help manage expectations, establish trust, and ensure that everyone understands the demolition plan, a key reason Total Wrecking is known for creating “raving communities” as much as successful projects.

LEARN MORE

Every project Total Wrecking takes on is guided by its “Four Pillars” philosophy:

Raving employees, Raving owners, Raving vendors, and Raving communities.

These pillars define how the company measures success: not just by what comes down, but by the positive impact left behind. By treating each city like its own, Total Wrecking ensures employees perform better, clients are more satisfied, and communities feel genuinely cared for.

Explore Total Wrecking’s selective demolition services and view their project portfolio to see how they bring precision and professionalism to every urban demolition challenge.